Absorption and flue-gas silencers

Individual and effective splitter silencers

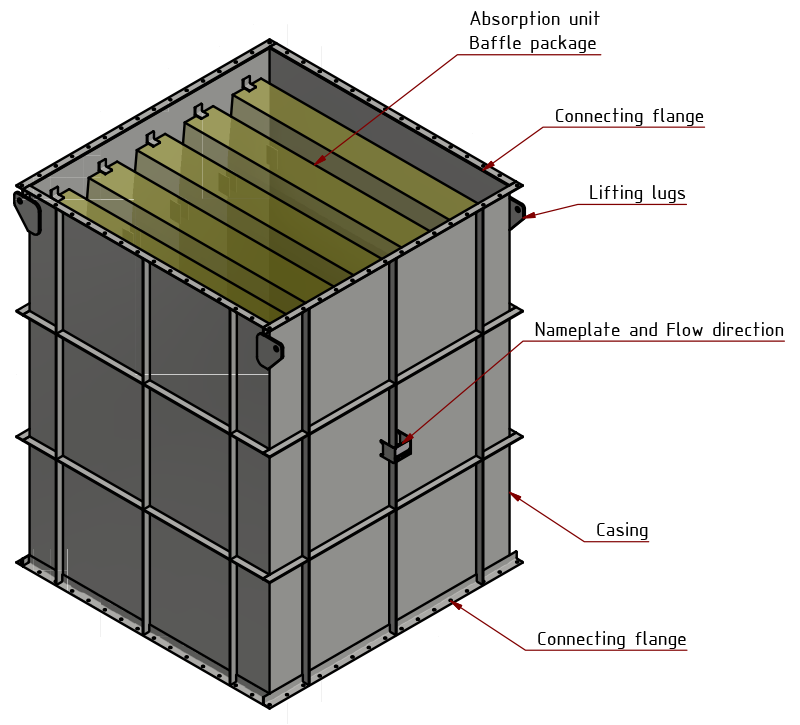

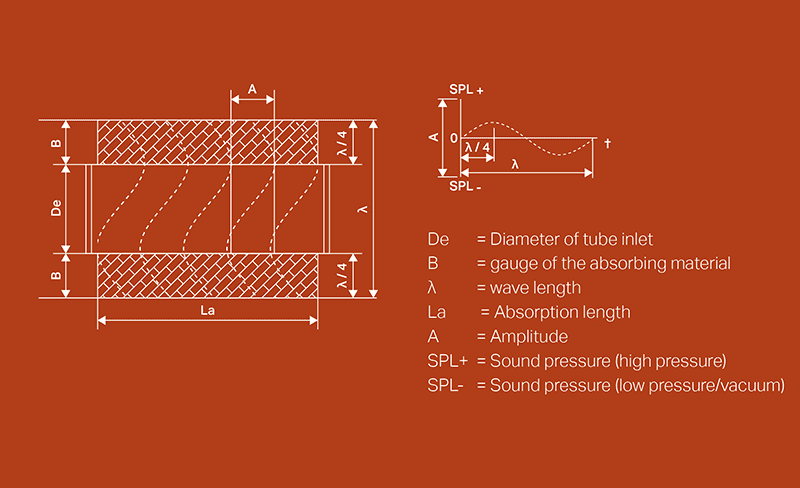

Absorption and flue-gas silencers are characterized by their installation. Wherever air or gas escapes or is sucked in, noise is generated, which can be reduced using silencers. In this type of silencer the flow of the gas is guided between the baffles, which allows the sound waves to be absorbed by the material. The sound energy is then converted into thermal energy.

The internal components of absorption and splitter silencers are filled with highly effective material specially made by our team. Thanks to these remarkable water and fire-resistant materials, our solutions consistently achieve a high degree of sustainability and withstand even the most extreme conditions.

In the case of strong air or gas flow, we use additional transparent cover layers next to perforated sheets. The structure of our internal absorption components is also individually adapted to meet these special requirements.

We offer solutions for the following applications and plant types:

- Turbines (intake and pressure side)

- Fans (intake and pressure side)

- Intake pipes

- Blow-out or exhaust pipes

- Power plants (bypass and boiler)

- Air separation plants

- Gas plants

- Chemical plants

- Petrochemical plants

- Paper production

- Steel production

- RLT-plants

- Acoustic requirement (sound pressure or sound power level)

- Output spectrum (third-octave or octave band)

- Medium (air, flue-gas, ...)

- Mass flow rate [kg/s] or volume flow [m³/h]

- Temperature [°C]

- Type and quantity of noise sources

- Permissible pressure loss of the silencer [Pa, mbar]

- Nominal connection widths [mm]

- Desired material

- Possible special components

The silencers manufactured by Furtak & Salvenmoser for process engineering plants are used worldwide. For example, one of these applications could be a gas and steam power plant (CCPP), which is one of the all-rounders in the field of electricity and heat generation. The Furtak & Salvenmoser GmbH silencers would be planned into the respective openings, after the heat recovery steam generator (HRSG, Economizer) and in the bypass of the turbine. Depending on the temperature and requirements, special constructions could be created that diminish the distortion and high flow speeds.

Individuality is our standard

Furtak & Salvenmoser GmbH stands for quality silencers, which are designed according to the specific needs of the client and the particular requirements of the individual industrial plants.

The design and calculation are based on innovative 3D tools, which allows for the precise manufacturing of the fastening and guide mounts. We also work with the highest quality materials approved for a temperature range of -196 °C to 670 °C.

We offer individually tailored solutions for your acoustic needs

- Concept and design

- 3D design and detailed construction

- Calculations and stability

- Project management

- Manufacturing

- Testing and approval

- Transport, packaging, and customs clearance

- Construction site management